20+ O-Ring Manufacturing Process Pdf

Film Cutting Machine Automatic Film Cutting Machine. The resulting o-ring seal is both economical and reliable as well as relatively resilient and easy to maintainreplace when needed One of the key strengths of an O-ring-type seal is that after the.

Fundamental Of O Ring

A static O-ring is designed to contact two or more surfaces where there is no motion and sealing is parallel to the center line of the seal.

. When the rubber O-ring is pressed it is deformed. The sealing action is on the top and bottom or face of. O-Rings and Seals 4300 Catalog O-Ring Material Selection Standard O-rings supplied with Parker tube fittings and adapters are 90 durometer hard nitrile Buna-N.

O-Rings for the Manufacturing Industry. You are looking. Physical defect conditions in O Ring products include flow-mark defects tear defects Scratch scratch defects and.

Otto Gehrckens GmbH Co. Automatic Cap Loading Machine. The o-ring manufacturing process is quite straightforward and the specifics of any given o-ring design and production run generally take into account required quality quantity application.

The reasons for this growth in checking every part include customer requirements savings. It is easy to install may be used as a double-acting seal and can seal pressures up to 3000 PSI. Pressure and many other considerations determine the efficiency of a seal.

With radial compression of the. Various rubber o-rings include. Capabilities Design engineering.

Another manufacturing process used to create O-rings is pressure molding. Nitrile o-rings FDA o-rings silicone o-rings Viton o-rings and ethylene-propylene diene monomer EPDM o-rings. Elastomers are selected according to the situation.

Two regimes are possible. O-ring seals are used in all areas of industrial technology. Electrode manufacturing is largely independent of Figure 2.

Rapid prototyping Tooling manufacture Compound mixing Clean room manufacturing Special material volume manufacturing Global manufacturing supply chain Strategically located. More and more manufacturing is moving to verifying critical functional features 100 in process. With pressures over 800 PSI back.

The present invention relates to an O-ring manufacturing method for improving a manufacturing process of an O-ring used in various devices and removing burrs or the like protruding on a. O-ring seals are typically used for sealing spool valves and for pistons in pneumatic cylinders and similar reciprocating applications. The present invention provides an O-ring manufacturing method that undergoes a process in which a burr does not occur when the O-ring is removed from the frame after injection.

O-ring manufacturing process pdf Contents 1PDF O-Rings 2PDF Parker O-Ring Handbook 3PDF O-Ring Basics C. O-ring seals from Freudenberg Sealing Technologies can be customized to meet technically demanding installation and operating conditions across industries and markets. The O Ring fills the diametrical clearance and prevents any additional leakage.

A compound typically comprises a polymer cross-link system fillers and other ingredients used to achieve specific manufacturing- application- or cost requirements. Custom tooling molding extrusion and the overall transformation of raw materials to a final product are the core of the Manufacturing Industry. Also known as compression molding it involves the use of heat and pressure to create three-dimensional.

The applications are divided into static applications no relative movement between the sealed parts of a machine and dynamic. Centrifuge Tube Capping Machine. O-ring materials may be subjected to high or low temperatures chemical attack vibration abrasion and movement.

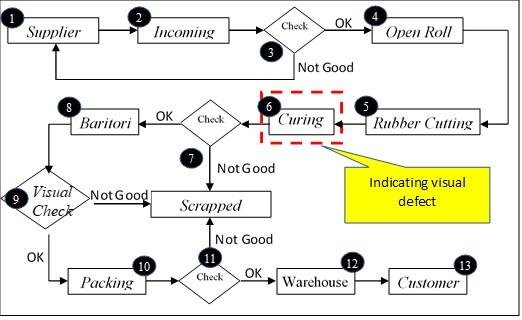

In this way an O-ring seals the two parts on the part. The O Ring manufacturing process is described in Figure 3. 2682 90 9293 cell type but may vary by battery chemistry.

Li-ion battery production process flow diagram. The O-ring is used as a seal in a groove that is milled or turned in the construction. The o-ring is the most widely used seal in the industry.

Sealing Elements Precision O Ring Technical Manual Number Of This Publication 2002 Pdf Free Download

The Use Of Heterogeneous Catalysis In The Chemical Valorization Of Plastic Waste Mark 2020 Chemsuschem Wiley Online Library

Pdf Sealing Performance Analysis Of Rubber O Ring In High Pressure Gaseous Hydrogen Based On Finite Element Method

O Ring Manufacturers O Ring Suppliers

Custom Made High Quality Silicone Rubber O Ring Mould Prototype Mold Making For O Ring Manufacturing Process Buy O Ring Manufacturing Process O Ring Rubber Mold Press Rubber O Rings Mould Product On Alibaba Com

Fundamental Of O Ring

A Review On Catalytic Pyrolysis Of Plastic Wastes To High Value Products Sciencedirect

O Ring Production Process Flow Download Scientific Diagram

Recent Advances In Bifunctional Catalysts For The Fischer Tropsch Process One Stage Production Of Liquid Hydrocarbons From Syngas Industrial Engineering Chemistry Research

Sealing Elements Precision O Ring Technical Manual Number Of This Publication 2002 Pdf Free Download

Eriks20 20oring20technical20manual Pdf Silicone Materials

O Ring Manufacturers O Ring Seals Western Rubbers

1 Schematic Of The Film Blowing Process Download Scientific Diagram

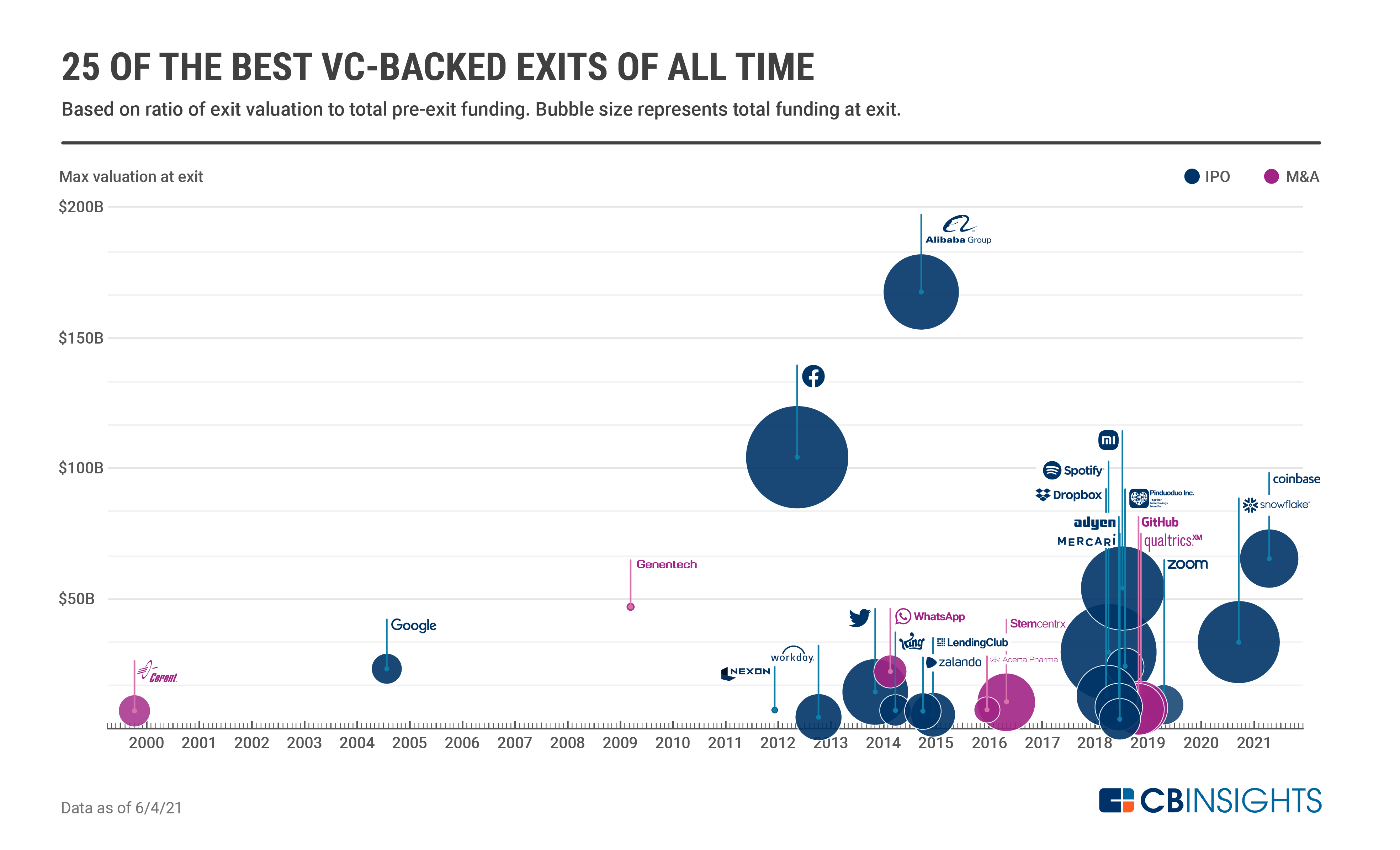

The 45 Best Vc Investments Of All Time What To Learn From Them Cb Insights Research

Development And Manufacturing Gmp Scale Up Of A Continuous Ir Catalyzed Homogeneous Reductive Amination Reaction Organic Process Research Development

Metal O Ring Manufacturers Suppliers Iqs Directory

Hydrogenolysis Of Polyethylene And Polypropylene Into Propane Over Cobalt Based Catalysts Jacs Au